What PWHT Classification Looks Like with the HSD Tester

Classifying post weld heat treatment (PWHT) seam welds from inspection data for Pipeline and Hazardous Materials Safety Administration (PHMSA) regulatory compliance can be challenging, but not impossible. With MMT’s HSD (Hardness, Strength, and Ductility) Tester, operators can accurately and reliably evaluate seam welds on pipeline assets for smarter integrity management.

Recognizing the Need

Acquiring most PWHT inspection data results in service interruption and damage to the pipeline due to destructive inspection methods. With the HSD Tester’s non-destructive material verification capabilities, operators can avoid downtime-associated costs and improve public safety by efficiently meeting regulatory requirements. Additionally, it is the only proven solution for non-destructive longitudinal seam determination.

How it Works

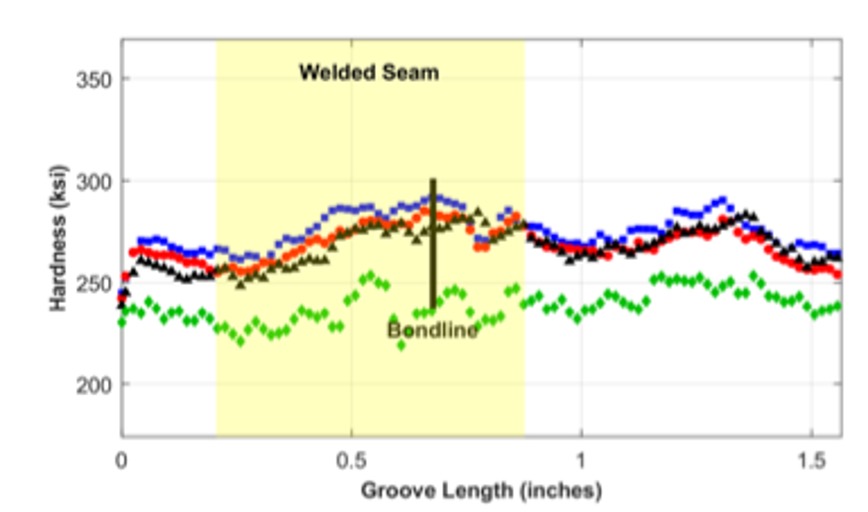

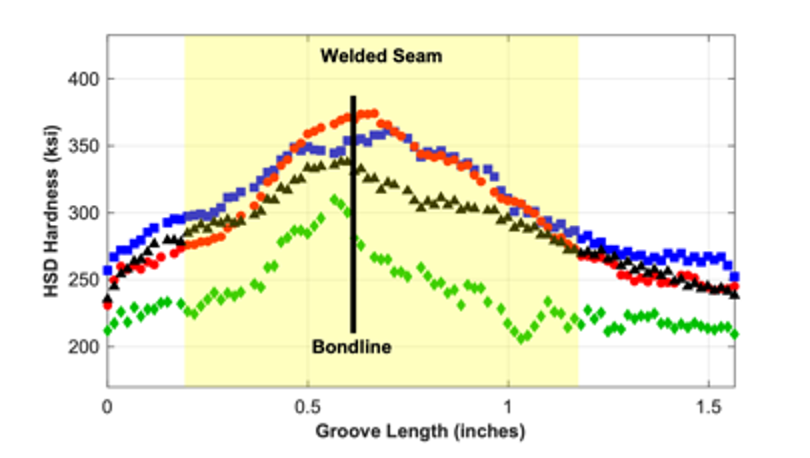

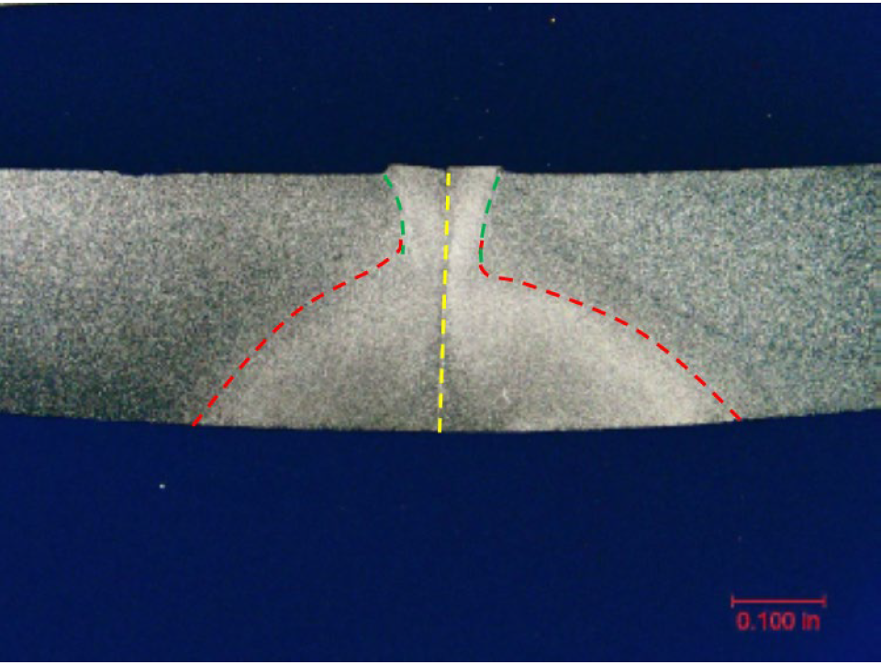

Material verification is needed across the industry to maintain the integrity and reliability of assets. The HSD Tester dependably and accurately quantifies the yield strength and determines the longitudinal welded seam type of pipelines. The seam type is identified by a scan over the longitudinal welded seam analyzing the hardness variation across the weld. The data classifies the weld fabrication process and the presence and quality of any present PWHT. The HSD Tester is distinct from alternative non-destructive evaluation (NDE) instruments because it utilizes frictional sliding to make imprints on the pipe surface, collecting hundreds of measurements across the length of a test. This results in a full profile of changes in material response, which is a critical factor when assessing the seam.

Dependability Defined

The HSD Tester has performed numerous integrity digs on pipes of various fabrication techniques such as seamless, double submerged arc welded (DSAW), flash welded, and electric resistance welded (ERW) development. When comparing the accuracy of laboratory tensile strength testing to the HSD Tester’s tensile strength prediction, the HSD Tester’s reliability has the advantage: it determines yield strength within 3ksi, using a 1-sided prediction interval at 80% certainty.

Generating Long Term Cost Savings

With the development of the HSD Tester, MMT has provided the most accurate material verification technology on the market, with the ability to classify seam welds. Operators can make smart pipeline integrity decisions while minimizing downtime, avoiding whole pipeline replacement, and preventing potential failure. Rather, operators can rely on a solution that is non-destructive and practical.

When looking at the big picture, MMT has presented the industry with an alternative for material verification that extends the life of old pipelines, eliminates service interruptions, and reduces the risk of incidents and failures.

Learn more about the HSD Tester here: bymmt.com/mmt-technology