Our Technology

We are the pioneer in frictional sliding technology and nondestructive toughness testing. Our advanced HSD tester stands out by collecting eight times more data points than any other market product, offering exceptional precision.

Our technology is vibration-resistant, eliminating the threat of data degradation or test failure due to pipeline vibrations commonly found in the field. We are innovators constantly developing new technologies and advanced AI to solve challenging energy infrastructure problems.

Our technology goes beyond current standards and the Mega Rule (RIN 2). With MMT and associated improved operational efficiency, you can reduce your overall cost of testing while exceeding industry compliance.

The HSD Tester

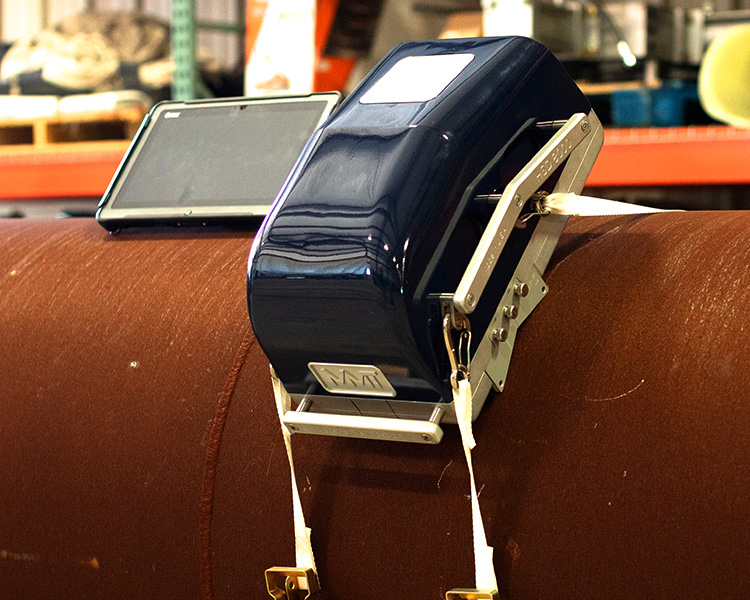

MMT’s Hardness, Strength and Ductility Tester (HSD) is a weather-resistant, ruggedized, process-driven instrument used by MMT-trained field technicians to provide YS (yield strength), UTS (ultimate tensile strength), API 5L Tensile Grade, seam weld classification and seam weld CVN (Charpy V-notch) toughness.

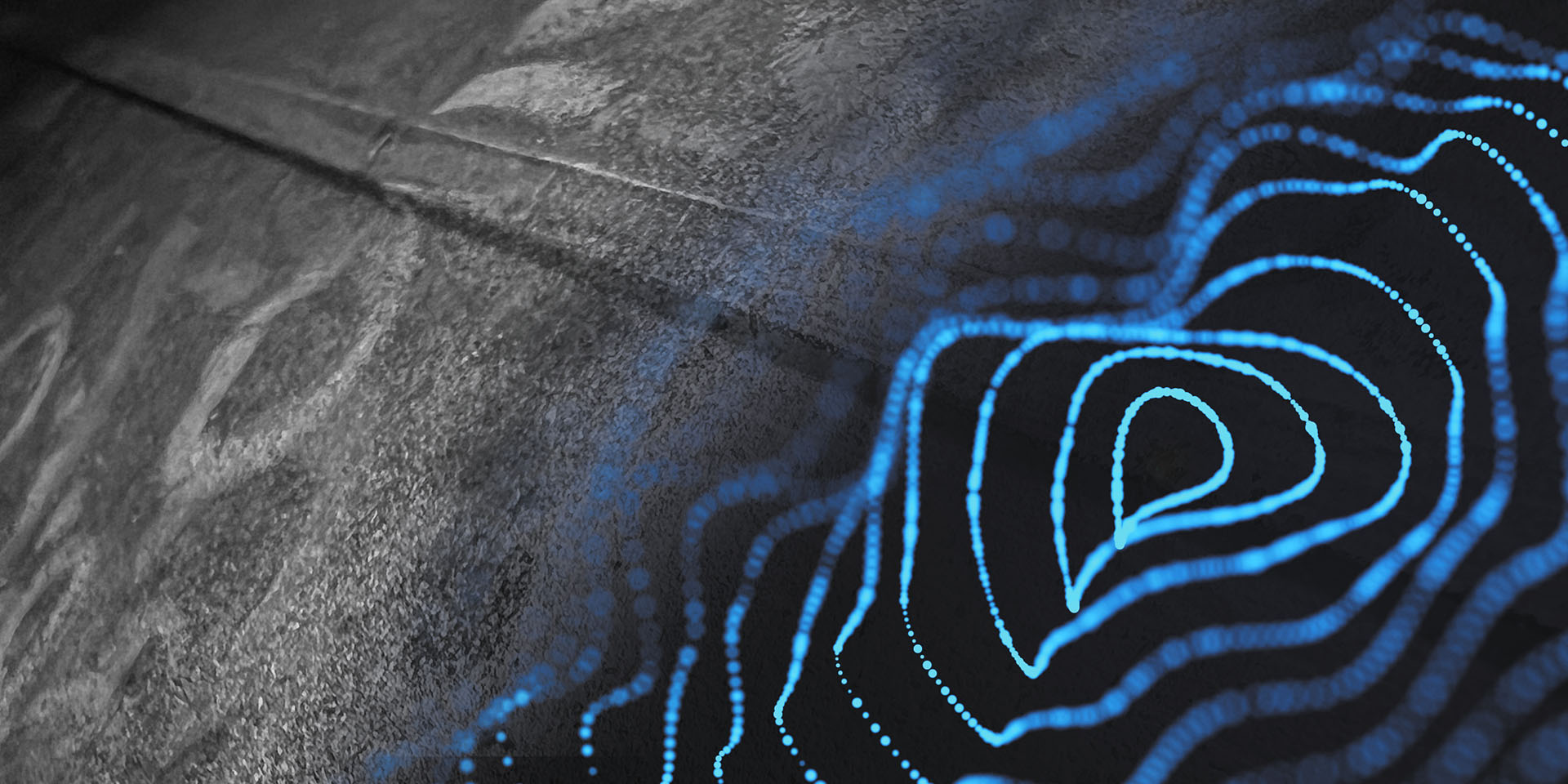

The HSD is the only field instrument utilizing the frictional sliding to yield laboratory-grade accuracy and results. This process imprints multiple long shallow grooves on the pipe body and across the long seam. This enables the collection of hundreds of measurements from a single test to sample a greater volume of material and provides reliable measurements

The HSD measures material response at targeted levels of deformation, creating a representative stress-strain condition closer to the initial yield and ultimate tensile strength of the material in addition to the collection and analysis of the material grain structure, chemical composition and finite element analysis.

MMT’s advanced frictional sliding technology creates multiple long, shallow grooves on the surface of a pipe and across the long seam, which allows for the collection of hundreds of measurements from a single test. This results in eight times more data points than traditional methods, improving accuracy.

Pipe Grade Verification: Prime Deliverable of the HSD Tester

MMT’s Seam Toughness solution enables pipeline operators to quickly and nondestructively obtain pipe grade verification, including accurate toughness values for ERW (electric resistance welded) seams.

HSD Testing is calibrated to differentiate between High-Frequency, Low-Frequency and Post-Weld Heat Treated ERW seams. This determination can significantly impact the safe operating conditions of assets by providing material properties above the conservative minimum values.

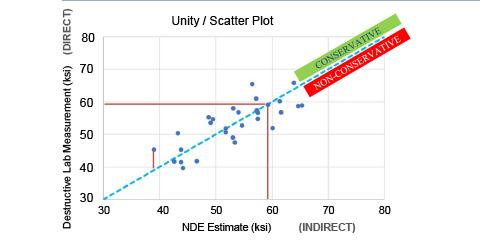

The HSD Tester is validated against laboratory test results, as shown in the unity plot to the right. MMT’s technology yields accurate, reliable results for dependable material verification data.

Process-Driven. No Downtime.

On-site testing takes an average of four hours per test location from start to finish. This includes all procedures of the HSD tester, full chemistry sampling and in-situ microscopy of the pipe material. An instant report is available immediately via the MMTConnect™ software.

The BTM Tester

Currently under validation and soon to be commercially available, MMT’s Blade Toughness Meter (BTM) measures and verifies material fracture toughness of the pipe body nondestructively without disruption of pipeline operation. The BTM is engineered to measure material toughness directly via a surface contact test vs. traditional pre-cracked or notched specimens loaded in tension or bending that require cut-outs and lab testing.

Technology Validation

MMT is committed to delivering cutting-edge technology that meets the highest industry standards. Our technology validation process is rigorous and thorough, ensuring our solutions perform at their best in real-world conditions. We verify the accuracy, reliability and efficiency of our instruments and techniques through extensive testing and validation. At MMT, we take pride in providing our customers with validated technology that empowers them to make informed decisions, ensuring their operations’ safety, integrity and success. Discover the power of MMT’s validated technology.

Sophisticated AI and Modeling Technology

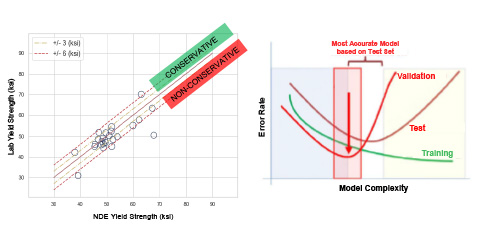

MMT’s validated non-destructive verification processes eliminates the need for destructive testing of cutout samples to obtain material properties. Our machine learning models are trained using an existing dataset and perform differently when testing unknown pipe samples (blind). By employing one-sided tool tolerance, we can conservatively account for measurement uncertainty, ensuring more accurate and reliable results.

Our Programs

Lease or Buy Equipment

MMT offers equipment sales and leasing options, comprehensive training programs, and ongoing maintenance services. We prioritize forming partnerships with those who invest in our cutting-edge MMT technologies.

MMT sells and leases equipment and training directly to NDE Service Companies to perform the service to pipeline operators with MMT technology.

Discover how our services and technology can benefit you, whether you’re an operator or an NDE provider. Learn more today!

Contact Us