Reporting What Matters: In-Depth Look At Using MMTConnect™ Reports For Seam Weld Identification

The welding process used for pipelines significantly affects the final material properties of the end product. However, many pipelines in the United States are vintage. Prior to around 1970 when these pipes were made, manufacturers lacked the advanced technology and knowledge of potential threats that we have today. Correctly identifying the weld seams on your pipes is vital for understanding and protecting against potential threats. Using MMT’s material verification technology and comprehensive reports, you can fully understand your pipeline and ensure its continuous reliability.

Impacts of Vintage Seam Welds on Modern Day Asset Integrity

According to PHMSA, over half of the gas transmission pipelines in the United States were manufactured over 50 years ago. Historically, manufacturers used vintage methods, such as lap and hammer welds, ERW-LF, flash welds, and single sub arc methods. These methods are now associated with specific material property threats, such as hard spots, porosity, and impurities that can make the pipelines unreliable and lower their estimated maximum allowable operating pressure (MAOP).

MMT’s material verification field assessment can identify all known seam types, including submerged-arc-welded (SAW), flash-welded, lap-welded, seamless, and electric-resistance-welded (ERW) pipes. For ERW seams, the HSD Tester can further determine if the low frequency (LF) or high frequency (HF) manufacturing process was used and whether an effective post-weld-heat-treatment was applied.

Comprehensive Reporting for Identifying Seam Welds

Accurate and reliable material property information is critical to managing asset integrity. That’s why MMT’s HSD Tester and MMTConnect™ seamlessly integrate to produce multiple reports that give you clear and accurate material verification information.

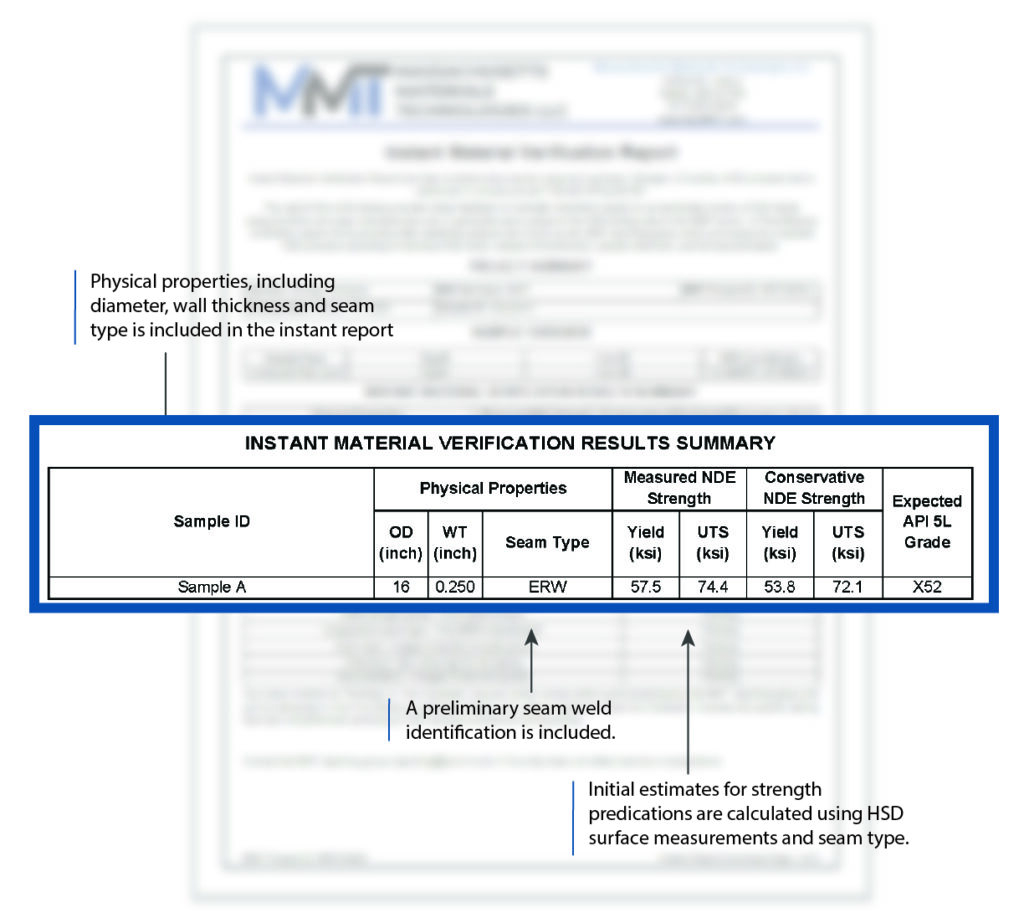

Instant Report. In the automatically generated instant reports, operators receive a preliminary overview and clear summary of testing results within 12 hours after the tested sample’s data is uploaded to the server. This summary includes physical properties (diameter, wall thickness, seam type) and preliminary strength predictions based on HSD surface measurements and manufacturing type.

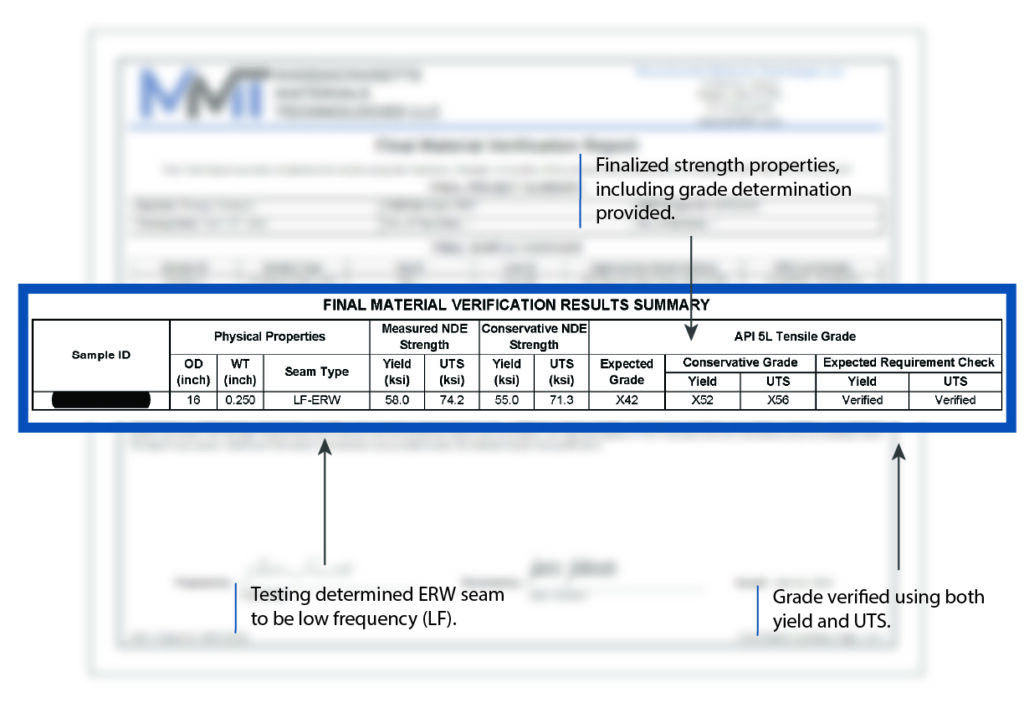

Final Report. For the final report, measurements are fully reviewed by MMT’s reporting team. The reviewed physical properties are reported along with the final strength measurements using MMT’s complete material strength prediction model which combines HSD surface measurements, seam type, microstructure grain size, and chemical composition. The final report also further classifies any present ERW seam as LF, HF, or PWHT.

Final reports include a final pipe body tensile grade determination based on a conservative shift from the final strength measurements. Users can use the final report to understand these elements for their pipeline:

- Informational Ultrasonic Testing (UT) wall thickness measurements

- Base metal test report, with chemical composition, grain size, and material strength

- Welded seam report, with ERW seam identification

In this final material verification report, finalized strength properties are provided and a grade determination is made based on conservative measurements. For this report, an expected grade of X46 was provided by the operator and HSD Testing was able to verify the grade based on both Yield and UTS. Additionally, the ERW seam type was classified as LF ERW.

Because the seam weld is LF ERW, the operator is now aware that that pipe is at an increased risk, as LF ERW pipes are associated with seam corrosion, excessive wall thickness reduction, hook cracks, and inadequate bonding. Certain types of LF ERW seams are notably less reliable than HF ERW seams because at the time the low-frequency method was used, engineering specifications and quality control programs were not standardized. Knowing this information, operators can take the appropriate steps to further identify threats and prevent possible future incidents.

How Your Integrity Management Benefits with the HSD

In addition to providing best-in-class analytics using a well-developed pipeline asset database for validation comparisons, the HSD provides:

- Stronger scientific basis behind the measurements

- Superior implementation of the measurement method with field equipment that performs in the field as good as in the lab

- Single package that includes mechanical testing, chemistry and microstructure of the pipeline steel

As a material verification tester with PHMSA-accepted methodology, the HSD and MMTConnect™ reporting meet and exceed regulatory standards. In a PRCI NDE 4-8 blind test comparison, MMT’s HSD Tester was the “best performing technique.”