IPC 2024: Non Destructive Evaluation of Pipe Seam Toughness Via Frictional Sliding

Seam toughness plays a crucial role in pipeline integrity, especially for vintage pipelines where original material records often lack fracture toughness data. Traditional methods for evaluating seam toughness typically require destructive testing, such as pipe cutouts, which can be costly and disruptive. This paper introduces a non-destructive evaluation (NDE) method using a frictional sliding technique to assess the toughness of electric resistance welded (ERW) pipe seams.

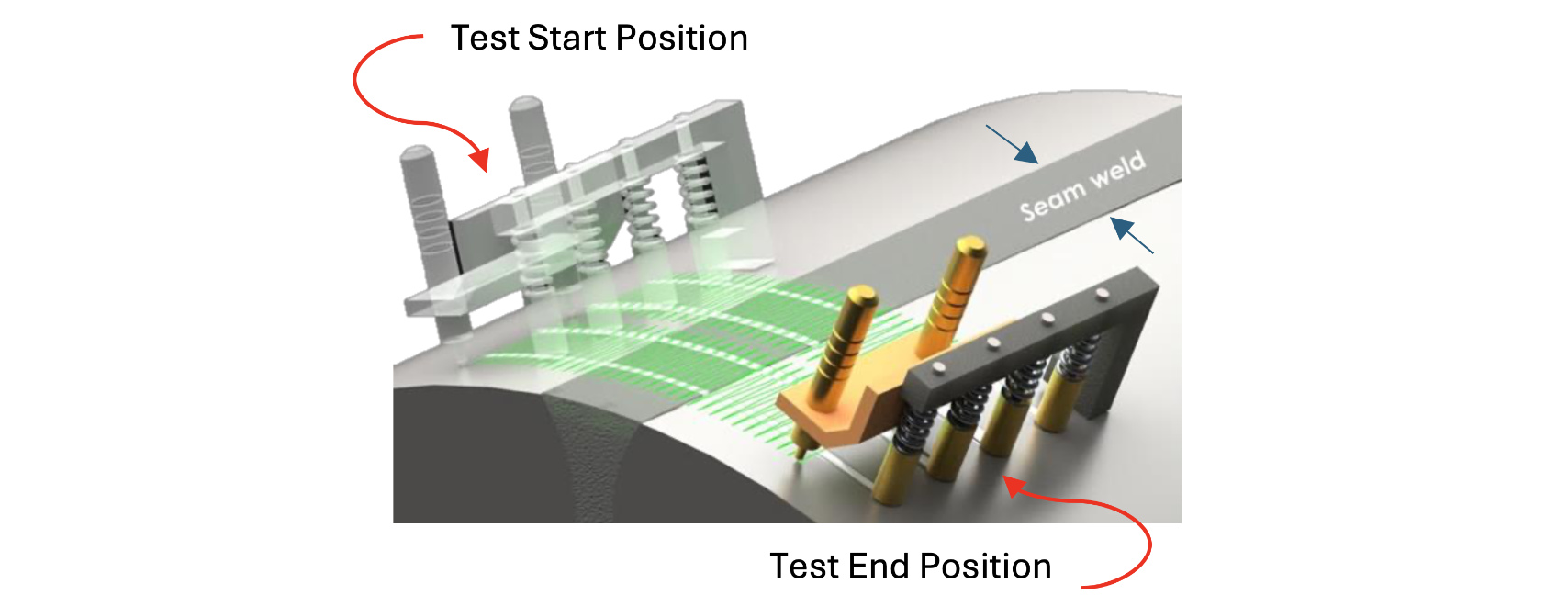

The method involves Hardness, Strength, and Ductility (HSD) frictional sliding tests, in which styluses with unique geometries apply a controlled load to the pipe surface, creating residual groove profiles. These profiles provide critical data on the material response, which, when combined with machine learning (ML) models, predict key aspects of Charpy V-notch (CVN) transition curves. The approach estimates transition temperatures and upper shelf impact energy, reducing the need for destructive testing while offering a practical alternative for confirming pipeline integrity.

Initial proof-of-concept testing on vintage ERW and Electro Flash Welded (EFW) pipes demonstrated strong correlation with lab-tested values, with transition temperature predictions within ±50°F and upper shelf impact energy estimates within ±10 ft-lbs. The results suggest that this field-deployable, non-invasive technique can provide valuable insights into seam toughness, supporting engineering critical assessments (ECA) and reducing unnecessary pipeline excavations.

Download the Presentation for IPC 2024

Intisar Rizwan I Haque1, Ryan Lacy1, Simon Bellemare1

1Massachusetts Materials Technologies, LLC